We are very pleased to have been awarded the contract for three state-of-the-art test systems for JULABO – one of the world’s leading manufacturers of temperature control technology for heating and cooling applications.

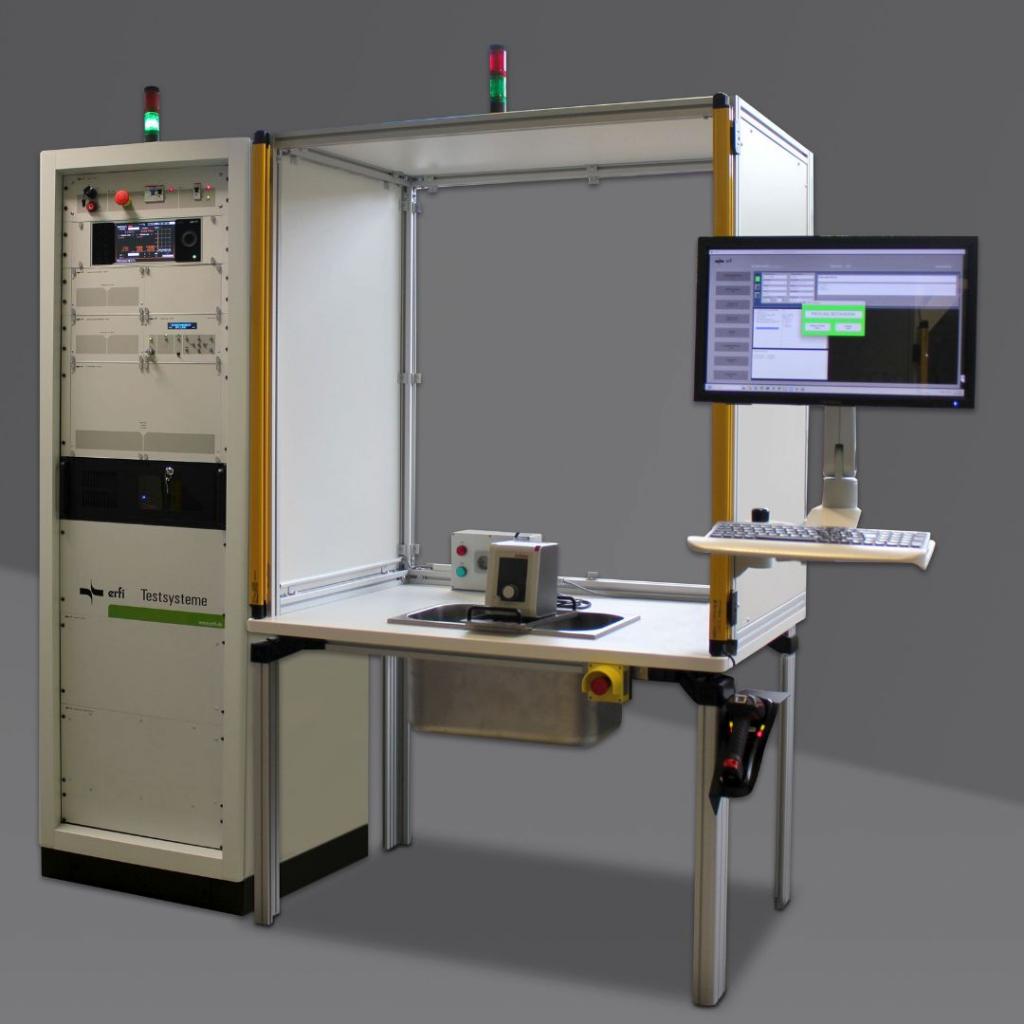

With the new erfi End-of-Line test systems, electrical safety and functional tests will be carried out even more efficiently and precisely in the future – directly at the end of the production line. A strong step forward for improved quality, safety, and efficiency!

These tests can be performed with the new systems:

- High Voltage (Dielectric) Test

- Insulation Resistance Test

- Protective Earth (Ground) Conductor Test

- Leakage Current Test

- Electrical Power Measurement

The test systems feature high-end components such as:

1. A professional safety and power measuring device from the modern elneos six series, capable of measuring all electrical parameters such as active power, apparent power, reactive power, current, voltage, power factor (cos phi), frequency, and more.

2. The CANclass Compact Tester model TS1.301 (current limited to 3 mA) for protective earth conductor testing, high-voltage and insulation testing, as well as single-phase leakage current testing.

3. A modern AC source: HV warm insulation isolation transformer (0–260 V / 16 A) as a voltage control unit, managed by the advanced control center of the elneos six system, including power measurement (single and three-phase).

4. A frequency converter for switching between 50 Hz and 60 Hz (for export to the USA).

5. Integrated PLC from Beckhoff.

6. Barcode reader and transponder login device for fast user authentication using personal chips.

7. CANDY test software with highly flexible and dynamic test planning – including features such as bypass and reintegration after repairs, along with a variable automatic logout function.

A sincere thank you to the team at JULABO Seelbach for placing their trust in our technology. We look forward to continued collaboration and many successful test cycles!